-

-

Call Now +91 9833287656

Fabrication

Pipe spool fabrication is fabrication (cutting, bevelling, welding) of metal pipes and elbows in order to pipe lines or pipe structures. the word pipe spool is used often in the oil and gas industry and in the offshore industry. most spools are manufactured in pipe spool fabrication shops where they have machinery for cutting, sawing, bevelling and welding.

Types of Fabrication

LR Bend

This Long Radius Bend is widely found applications in different industries such as ship building, power plants, water treatment plants, refineries and petrochemical industries. This Long Radius Bend is fabricated in various types, schedule class, range and sizes according to the demands of customers. Furthermore, it is dimensionally accurate and corrosion resistant.

- Type : Seamless / Welded / Fabricated

- Size : 2″-48″(DN50-DN1200)

- Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A403 / A234 / A420 / B366

- Dimension : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 etc.

Piping Spool

Pipe spools are often flanged to facilitate the connection to other spools. The fabrication of these spools is normally performed by specialist fabrication companies which are equipped with the required infrastructure. The specialist fabricators work under defined set of quality management criteria to ensure the accuracy of fabrication in order to achieve the roper fit at site and to maintain the required technical parameters defined by the client.

Get A Quote

Manufacturing Process

-

-

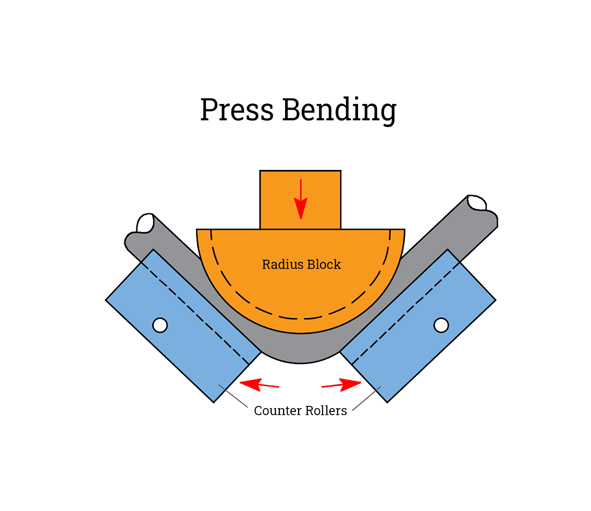

Press Bending is a quick bending method for symmetrical parts and requires no lubrication and cleaning. However, it is difficult to make a smaller degree of bend using this method. It offers no support on the tube internally; hence it is prone to deformation in the internal and external curvatures. It often produces an oval cross-section, depending on the tube’s wall thickness. This method of bending is difficult to control and is only used when a consistent cross-section is not required.

-

-

Rotary Draw Bending is a suitable method to create precise bends with constant CLR and constant diameter, giving minimal ovalization. Some of the applications of this technique are found in pipe fittings, instrument tubing, handrails, automotive and aerospace parts. This method is also used for hollow sections with different cross-sectional shapes (e.g., square, oval). A smooth and aesthetically-pleasing bend is produced from the right tooling used matched to the application.

-

-

3-roll bending is also used for producing work pieces with large bending radii. The method is similar to the ram bending method, but the working cylinder and the two stationary counter-rollers rotate, thus forming the bend. Normally there are 2 fixed rollers and one moving roller and the work piece is passed forward and backward through the rollers while gradually moving the working roller closer to the counter rollers which changes the bend radius in the pipe.

-

-

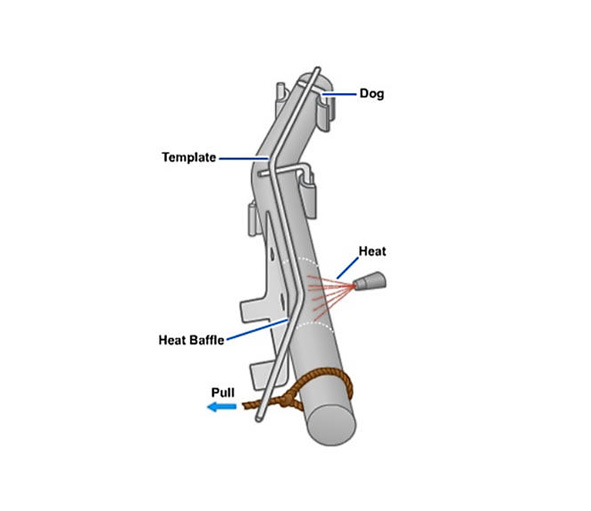

In heat induction bending, the tube is supported on the front end, and the bend clamp is located in between the rotating arm and the rear end. The front end of the tube is clamped in the pivot arm and is pushed gradually to the bend clamp from the rear end. As the tube is gently pushed, it passes through an induction coil where it supplies heat at a point tangent to the bend radius. The pivot arm is roughly equal to the bend radius of the workpiece. The working temperature depends on the material, usually ranging from 430°C – 1,200°C. After bending is made, the workpiece is quenched in air or water spray.

-

-

In the sand packing process the pipe is filled with fine sand and the ends are capped. The pipe is then heated in a furnace to 870 C or higher. The pipe is then placed on a slab with pins set in it. The pipe is then bent around the pins using a winch, crane, or some other mechanical force. The sand in the pipe minimizes distortion in the pipe cross section. It is an old process but one that hasn’t really been improved on for its flexibility when it comes to unique applications, and so is still in common use.

we are the manufacturers in the various Materials

-

Stainless Steel

ASTM A403 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L

Heat Treatment Explore More -

Carbon Steel

ASTM A234, ASME SA234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70, ASTM A420 WPL3, A420 WPL6.

Heat Treatment Explore More -

Alloy Steel

ASTM A234, ASME SA234 WP1 / WP5 / WP9 / WP11 / WP22 / WP91

Heat Treatment Explore More -

Duplex & Super Duplex Steel

ASTM A815, ASME SA815 UNS S31803, S32205, 2205, UNS S32750, S32760, S32950, 25070

Heat Treatment Explore More -

High Nickel Alloy

Nickel 200, 201, Monel 400, K500, Incoloy 800, 825, Inconel 600, 601, 625, Hastelloy C276, C22, Alloy 20, Titanium (Grade 2 & 5), Cupro-Nickel 70/30, 90/10.

Heat Treatment Explore More